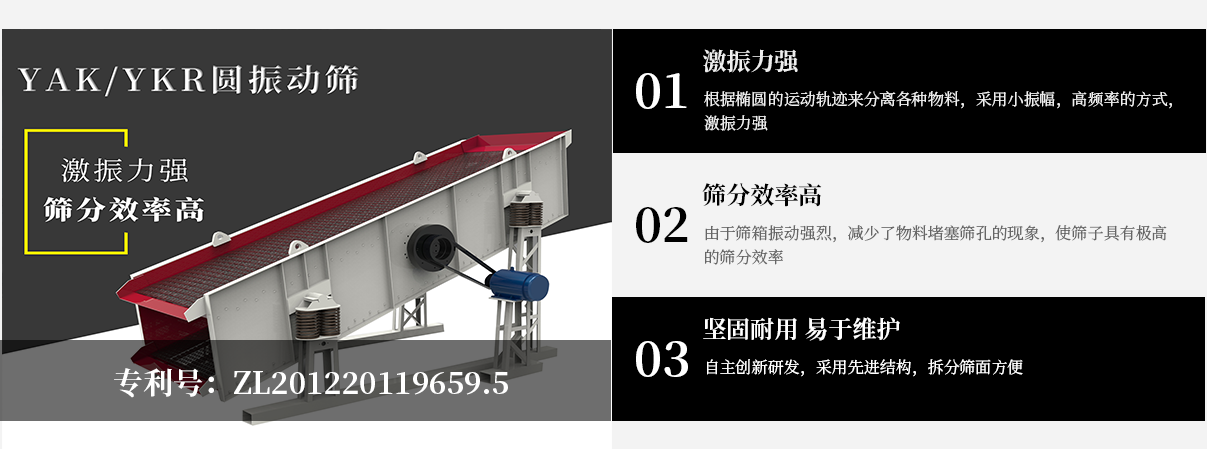

In 2008, Longjian Group independently developed the first thin oil circular vibrating screen. One equipment is equivalent to the production capacity of two similar products, and it is hailed as the "Western Sieve King" by the majority of users. As we all know, the screening efficiency of the vibrating screen directly affects the production efficiency of the entire stone and sand production line. Once the Longwang Group's "Western Sieve King" was launched, it won the favor of the majority of sand and stone industry bosses.

Longjian Group has focused on the mining machinery industry for nearly 30 years, and specializes in providing circular vibrating screens, jaw crushers, re-hammer crushers, hydraulic cone crushers, vertical shaft impact crushers, impact crushers, high-fine sand crushing Machine and other crushing sand making equipment. Our company has launched a series of YAK / YAR circular vibrating screen products, which have the characteristics of advanced structure, strong excitation force, low vibration noise, convenient maintenance, ruggedness, etc., and are widely used in product classification in mining building materials, energy and other industries.

So, how should we improve the screening efficiency of the circular vibrating screen?

1. Improve the opening rate of the sieve plate. The high opening rate is conducive to improving the screening effect. Generally, the stainless steel welded sieve plate has a high opening rate, which can improve the screening efficiency.

2. Adjust the stone material input method. If the feed is not fed along the full screen width, it will cause the screen surface not to be fully utilized and affect the screening efficiency. A feeding device can be added at the feed port to make the material enter evenly. Adjust the tilt angle of the screen machine. Properly reducing the inclination angle can reduce the thickness of the material and achieve thin material screening.

3. Use the self-cleaning sieve plate. Use self-cleaning sieve plates to reduce the batter rate of sieve surface. The automatic net cleaning device reduces the probability of blocking holes on the screen surface and improves the screening efficiency.

In summary, Longjian Group recommends that you can adjust the weight of specific vibrating screens and circular vibrating screens, and in the process of using, pay attention to the problems of positive obliques, and improve the screening efficiency of circular vibrating screens through reasonable adjustments. Welcome to visit the field. Longjian Group's official website http://m.ousuu.com.cn.

-

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line -

The 2022 Spring Festival holiday notice of Longjian Group

The 2022 Spring Festival holiday notice of Longjian Group -

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021 -

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities -

.png) Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration"

Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration" -

How to create green mines and green factories?

-

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province -

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association